Which HVAC Pipe Bender is Best for Your Production?

In HVAC system, pipe bending is necessary to ensure the proper installation and system efficiency. Whether you are using air conditioning, heating, or ventilation systems, the well-bent pipes are an important factor in delivering optimal airflow and refrigerant circulation. In the production of pipe bending, precision and consistency are the key, and choosing the proper pipe bending machine is the key point to achieve this.

Choosing the right HVAC pipe bender can greatly improve the efficiency, reduce waste, and streamline your production process. But, there are various types of pipe benders selling on the market, how to choose the correct type for your production? In this blog, we will talk about all the factors you need to consider before choosing your ideal HVAC pipe bender.

Understanding HVAC Pipe Benders

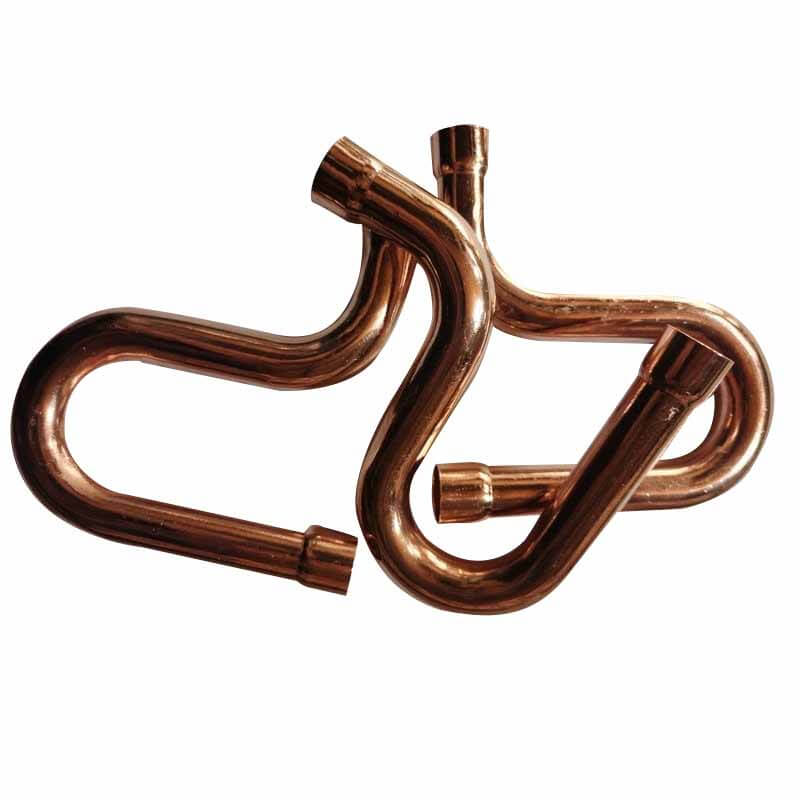

An HVAC pipe bender is a specialized tool or equipment that is used to bend copper pipes, aluminum pipes, or steel pipes, without causing any deformation or damage. Mainly to ensure:

- Accuracy: Bending the pipe precisely can ensure the HVAC systems fit perfectly within a building’s layout, minimize the leaks or blockages in airflow or refrigerant lines.

- Consistency: In the large volume production, the repeated tasks require consistency. The HVAC tube bender can guarantee the uniform bends across multiple pipes and ensure the system reliability.

- Speed: For mass production, time is money. The hydraulic or CNC tube bender can significantly increase the pipe bending speed, an ideal choice for industrial production.

Types of HVAC Pipe Benders

Choosing the right type of HVAC pipe bender depends on your production scale and the specific request of your project. Below are the three main types of HVAC pipe benders and their pros and cons:

Manual Pipe Benders

Manual pipe benders need physical effort to bend pipes. They are suitable for small projects and used to deal with soft materials, such as copper and aluminum.

Pros of Manual Pipe Benders

- The price is affordable and widely used in small projects or temporary on-site operations.

- Portable, easy to carry to where you need it.

- No external power supply required.

Cons of Manual Pipe Benders

- Limited bending capacity, not suitable for large diameter pipe or hard metal pipe.

- The working speed is slow, not suitable for large volume production.

- It is labor-intensive, and the bending results are likely to be inconsistent.

Hydraulic Pipe Benders

The hydraulic pipe bender adopts the fluid pressure to bend pipes, offering more power and precision. These machines are suitable for larger projects and bending tougher metals.

Pros of Hydraulic Pipe Bender

- Strong bending ability, suitable for bending thicker, tougher metal tube.

- Precise and consistent bends, ensuring high accuracy.

- Suitable for medium to large-scale production environments.

Cons of Hydraulic Pipe Bender

- More expensive than manual benders.

- Heavier, not portable. Requires a certain amount of space in your workshop.

- Hydraulic components require regular maintenance.

Electric Pipe Benders

Electric pipe benders are designed for large volume production. They work automatically and can be programmed for precision and speed, this is the most efficient choice for large-scale operations.

Pros of Electric Pipe Benders

- Fast and efficient, the ideal choice for large-scale production.

- Can be programmed, high precision, delivers consistent results with minimal human intervention.

- Suitable for various materials and pipe sizes.

Cons of Electric Pipe Benders

- Initial Cost is high, not suitable for small-scale production.

- Require power and may take up more workshop space.

- Maintenance and repair costs are relatively high and require regular training of professional operators.

Key Factors in Choosing the Best Pipe Bender for Your Production

When deciding which HVAC pipe bender is best for your production, you have to consider below factors:

Production Volume

- Frequency: How often do you need to bend the pipe? If your production volume is low, the manual type is enough. For high volume production, the hydraulic and electric types are more efficient.

- Quantity: If you need to bend the pipe in large quantities, we suggest you use a hydraulic type or an electric type, which will help to improve your productivity.

Pipe Material

- Copper: This material is soft and easy to bend, can use manual or hydraulic pipe bender to handle. This material is used in HVAC systems for refrigerant lines.

- Aluminum: Lightweight and also easy to bend. But you need to take care to avoid cracking. This material is generally bend by hydraulic or electric tube bender.

- Steel: This material is strong and durable, so they need powerful tools, such as hydraulic and electric pipe bender.

Pipe Diameter and Thickness

- The capacity of the pipe bender you choose must be able to cover the maximum diameters and thicknesses you work with. The manual type can only bend small diameters, but the hydraulic and electric type can bend larger pipes with greater wall thicknesses.

Precision Requirements

- Accuracy: HVAC systems rely on precisely bent pipes to maintain proper airflow and refrigerant circulation. So, even the small inaccuracies can lead to inefficiencies, leaks, or failures in the system. If your project needs highly precise pipe bending, the hydraulic pipe bending machine or the electric pipe bending machine can help you ensure the bending quality.

Operator Skill Level

- Manual Benders: These pipe benders require more operator and physical effort. They are easy to operate but need proper training.

- Hydraulic Benders: More powerful, but need training for safe and effective use, particularly in high-capacity environments.

- Electric Benders: Once programmed, these benders are the easiest to operate, but they may require specialized training to set up and maintain. If your production request minimal manpower, but consistent bending results, this machine is your best choice.

TubeBenderN is the manufacturer of HVAC pipe benders in China. We produce the hydraulic and electric types, which are suitable for industrial mass production. If you are looking for the tube bending machine for the HVAC system, contact us below to get your bending solution today!

You may also be interested in:

Denis Lau

Denis Lau has 20 years of work experience in the metal processing industry. His major in university was mechanical engineering, and after graduation, he started from the bottom of the workshop, gaining extensive hands-on professional experience and the ability to tackle challenges from various industries.