The Ultimate Guide to Cold Saw

We are going to talk about cold saw in depth today, mainly involving their features, advantages, applications and maintenance. We will talk about the parts and components of cold saws for different industries that benefit from their capabilities. If you want to improve the productivity in your metal fabrication factory, get great precision in manufacturing, and explore more possibilities in construction, you will get all you want to know from the ultimate guide to cold saw.

What is a Cold Saw?

A cold saw is a specialized cutting machine for cutting metal tubes with a precise and efficient cutting result. The cold saw blade can cut various materials, including steel tubes, copper tubes, stainless steel tubes, etc. If you use conventional saws to cut these materials, your cutting tool will be very easy to generate excessive heat during the working process. But, if you use cold saws to cut the material, the heat generation will be reduced, due to lower speed, at the same time, you will get a perfect cutting result. With the saw’s strong construction and advanced blade technology, such a cutting style will make tube cutting a clean and accurate cut with little burrs and distortion.

What are the Components of Cold Saws?

- Motor: The engine of the cold cut saws, supplies force to move the blade.

- Cutting Blade: The material of cold saw blades is high-speed steel (HSS) or tungsten carbide-tipped (TCT).

- Blade Guard: A container that protects the cutting blade and keeps debris from flying around, assuring operator safety.

- Cutting Table: A strong platform which could hold the cut material in place.

- Vise or Clamp: Firmly hold the cutting material in place and make it stable while cutting.

- Base and Frame: These parts supply the stability and support to the saw, reducing vibration during machine working and improving cutting precision.

- Controls and Changes: Enables users to modify the cutting process, including on/off switches, speed controls, cutting angle changes, and depth adjustments.

How Does a Cold Cut Saw Work?

The Advantage of Cold Cut Metal Saws

- Precision Cutting: Industrial cold saws are widely used in applications, such as metal fabrication, construction, automotive, Plumbing and HVAC, pipe cutting, etc. with clean and accurate cuts.

- Productivity and Efficiency: Due to the high cutting speed and optimum cutting settings, steel cold saw works with shorter cycle times and higher productivity.

- Versatility: Industry cold saw can cut a wide range of materials, including tubes and profiles in carbon steel, brass, and stainless steel material. This feature will bring you more business chances in various industries.

- Heat Reduction: Cold cutting reduces heat generation and maintains the material’s structural integrity, cutting end is smooth and burr-free, reducing the need for additional finishing operations.

- Cost Savings: Using cold saw machines to cut metal tubes is a low-cost solution. After cutting, almost no material is wasted and no need for additional operation.

The Disadvantage of Circular Saw

- Limited Cutting Depth: Circular cold saws have limitations on the Max. cutting depth, check which machine size fits your cutting needs from our expert. This is the disadvantage if you require deeper cuts.

- Required Coolant System: To maintain optimal cutting performance and prevent heat buildup, circular cold cut saws rely on a coolant system. Of course, this requires additional setup and maintenance, including replenishing coolant and managing the disposal of coolant waste.

- Size and Weight: cold cut saw is often larger and heavier than some portable saws, mainly used in fixed workshops and industrial purposes. If you want to move the machine, cold saws may not be your first choice.

- Initial Investment: The purchasing cost of cold cut metal saws is often higher than some other types. However, the lifespan of the cold cut saw blade and cutting efficiency provided by this machine can cover your investment.

Here is the cutting capacity of the coldsaw which is produced by TubeBenderN for your reference. You can also check the details and ask for a quotation from our expert.

The Comparison of Metal Cold Saw and Band Saw

| Aspect | Cold Saw | Band Saw |

| Cutting Precision | High precision cuts | Good precision, slightly rougher cuts |

| Heat Generation | Low heat generation | Higher heat generation |

| Cutting Speed | Slower cutting speed | Faster cutting speed |

| Blade Longevity | Longer blade lifespan | Shorter blade lifespan |

| Versatility | Suitable for various materials | Versatile, handles a wide range of materials |

| Cutting Capacity | Suitable for smaller to medium-sized | Suitable for larger workpieces and deeper cuts |

| Portability | Less portable | More portable options available |

| Initial Investment | Higher initial investment | Lower initial investment |

When choosing cold saw or band saw, you need to consider your specific cutting requirements, materials, and other preferences. Cold saws offer high cutting precision and longevity, but have slower cutting speed than band saw, and are also less portable. Band saws provide good precision, faster cutting speeds, and more profitability options, but their blade lifespan is shorter.

How to Choose the Right Cold Cut Saw?

Before selecting the cold cut saws, you need to consider the following factors;

- Cutting Capacity: Check the maximum diameter and thickness that the saw can handle and see if they can meet your cutting requests.

- Motor Power: The motor that drives the saw must have sufficient power. High-horsepower motors are able to handle tougher materials and provide faster cutting speeds.

- Blade Type: Choose the right blade material and tooth design for your cutting material. HSS blades are best suited for cutting softer materials, whilst TCT blades excel at cutting tougher metals.

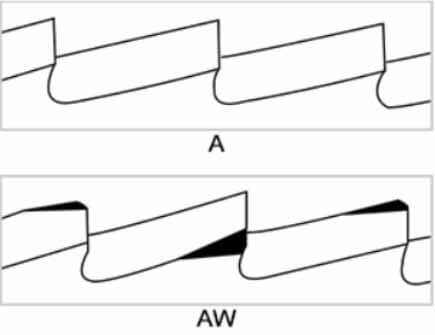

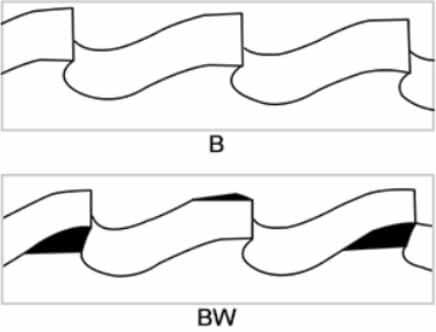

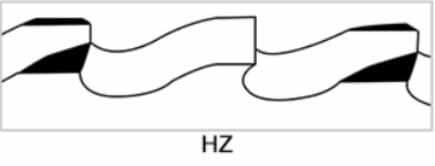

- Tooth Form of Cold Saw Blades

For thin metal slitting saw blades with a tooth pitch up to approx. 3.0mm

Advisable for cutting brass.

Tooth “A” is suitable for slotting materials.

All teeth of tooth “AW” are bevelled alternatively.

For tubes and profiles made of steel or non-ferrous metals.

Tooth “B” is suitable for very thin-walled pipes.

All teeth of tooth “BW” are bevelled alternatively.

For cutting solid materials.

Teeth are ground according to the roughing and finishing tooth system. The roughing tooth is approx. 0.2-0.3mm higher than finishing tooth.

- Surface Treatment of Cold Cut Saw Blades

White Colour

White colour is the original colour of the saw blade without coating.

Black Colour (Oxided)

Covered on the surface is a layer of iron oxide, which increases the wear resistance and overall life.

Suitable for general cutting work.

Gold Colour (TIN)

Coated with an excellent PVD coating for protecting the saw blade from wear, which is a good choice for iron-based materials and cutting conditions requiring resistance to both abrasive and abrasive wear.

Rainbow Colour (TIALN)

TIALN is a new multi-layer wear protection PVD coating. Recommended for high tensile strength materials and stainless steel.

Responds very favourably to high speed and feed rates as well as extreme working conditions.

Bronze Colour ( TICN)

TICN is a high-performance PVD coating suitable for severe abrasive wear-cutting conditions.

Recommended for high tensile strength materials and stainless steel.

- Adjustable Features: If you have a complicated cutting request, you need to consider if the saw is adjustable for different cutting angles, various speed controls, and cutting depth. You can get the best solution by consulting with our expert.

- Safety Features: It is better that the cold saw you purchase should equipped with blade guards, emergency stop buttons, and overload protection mechanisms, this could provide the operator a secure operating environment during production.

How to Maintain the Cold Cut Saw?

- Blade Inspection: Check the cold saw blade for any signs of wear or damage regularly. Replace worn-out blades promptly to maintain cutting quality.

- Lubrication: Follow the manufacturer’s instructions, and lubricate the blade and moving parts to reduce friction and maintain smooth performance.

- Cleaning: The debris and dust on the saw will affect the cutting accuracy and performance, you can use compressed air or a brush to remove them.

- Calibration and Alignment: Check and adjust the alignment of the blade, vise, and cutting table on a regular basis is necessary to maintain correct cuts.

- Technical Support: For any technique you can not solve by yourself, please contact the supplier to assist you.

FAQs about Cold Saws

Q: What safety precautions should I take when operating a cold saw to ensure my well-being?

A: When operating a cold saw, it is essential to follow the manufacturer’s instructions. Mainly means wearing proper personal protective equipment, including safety glasses, hearing protection, and gloves. Ensure that the work area is well-ventilated, learn the product manual, familiar with the machine emergency button.

Q: What are the power requirements for operating a cold saw, and can it run on standard electrical outlets?

A: Each model and its motor may require different power configurations. Some cold saws can run on standard electrical outlets, but some others can be customized according to specific conditions, you can ask our expert for details.

Q: Are there environmental considerations when using cold saws, such as waste disposal or emissions?

A: Cold saws are eco-friendly, due to their reduced heat generation and minimal emissions. The metal waste that can be recycled is an eco-conscious practice.

Q: How do I ensure the longevity of a cold saw blade, and when should I replace it?

A: You need to maintain the lubricate the saw blades regularly, in order to extend their service life. When you find the reduced cutting efficiency, increased burrs on the cutting material, or any visible signs of wear or damage, you need to replace the blades promptly.

Q: Can cold saws be used for cutting non-metal materials, like plastics or wood?

A: Cold saws are designed for cutting metal materials. We don’t recommend cutting non-metal materials, since this may result in blade damage and reduced efficiency.

Q: What are the differences between manual, semi-automatic, and automatic cold saws, and how do I choose the right type for my needs?

A: Manual, semi-automatic, and automatic cold saws differ in terms of their level of automation and complexity. Manual saws require operator control for each cut, while semi-automatic and automatic models offer varying degrees of automation. The choice depends on your production volume, cutting precision needs, and budget. Choose the best-fit cold saw, please consult with our expert.

Q: Are the cold cut saw blades singe use?

A: Cold cut saw blades are not single-use, but when the blades appear some wear, you need to find a local shop to grind the saw blade or buy a saw blade sharpener to grind the blade in your own factory.

Learn more about cold saw here.

TubeBenderN is the manufacturer of manual cold saws, semi-auto cold saws, and automatic cold saws. We can specifically customize the cold saw according to your specific tube cutting needs. Contact our engineer by filling in your request in the below form, they will get in touch with you within 10 minutes!

Denis Lau

Denis Lau has 20 years of work experience in the metal processing industry. His major in university was mechanical engineering, and after graduation, he started from the bottom of the workshop, gaining extensive hands-on professional experience and the ability to tackle challenges from various industries.