The Ultimate Guide to Choosing Cold Saw Blades

Cold saw blades are designed for precise and efficient cutting of metal materials and generally work in industrial settings. Different from other cutting saws, cold saw blades work at lower temperatures, this could reduce the heat buildup and minimize the material distortion.

The cold saw blades are widely used because they offer clean, accurate cuts with a smooth finish. Choosing a proper cold cut saw blade is very important to improve cutting efficiency, reduce wear and tear, and ensure high-quality cuts. In this blog, you will get all you want to know when selecting a cold saw blade and making the best choice for your specific needs.

What are Cold Saw Blades?

Cold saw blades are circular cutting tools designed for precise cutting on metal materials, they work at low speed with high torque to minimize the heat generation during the cutting process. Doesn’t like the traditional cutting method, this low temperature operation reduces the risk of thermal damage to both the blade and the workpiece, so the cutting results are generally clean, and the lifespan of the blades is longer.

Types of Cold Saw Blades

Industrial saw blades that are used to cut metal tubes can be made from different materials, they are used to cut different materials and sizes. Let’s see their main types.

HSS (High-Speed Steel)

HSS cold saw blades are made from high-speed steel, generally used for cutting mild steel, stainless steel, and other hard metals. The HSS saw blades have excellent resistance to wear and abrasion and can retain hardness at high temperatures.

Carbide-Tipped

The cutting edge of carbide-tipped cold saw blades are made from tungsten carbide, this material is harder than HSS, so these blades have excellent cutting performance and longer lifespan. The TCT cold saw blades are suitable for cutting aluminum, copper, brass, and other tough or abrasive materials.

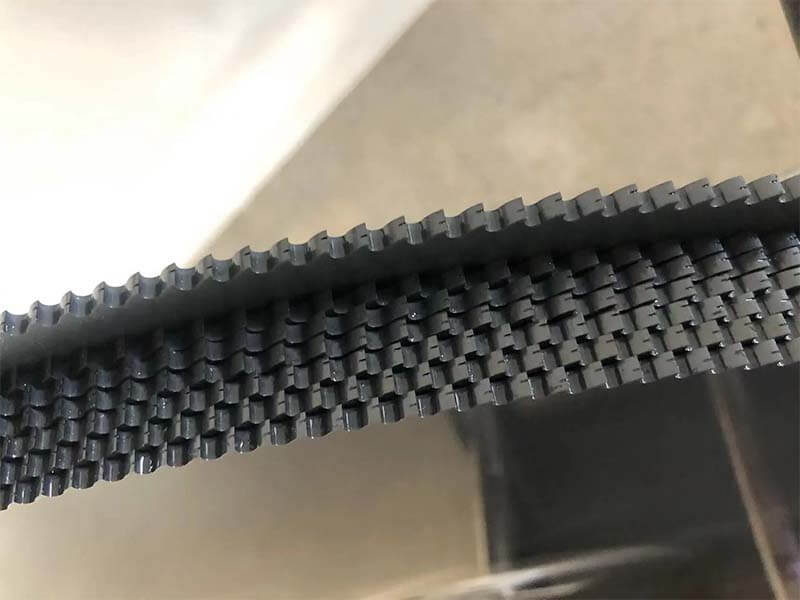

Segmental Blades

Segmental blades consist of a steel body with replaceable tooth segments made of HSS or carbide. The segmented design allows for easy replacement of worn teeth, greatly reducing the cost of maintenance.

Key Factors to Consider When Selecting the Cold Saw Blades

To perform the best cutting result, you need to choose the most suitable blade that fit your specific cutting task. Here are the key factors you need to consider.

Cold Saw Blade Material

According to the materials of circular saw blades, they can be divided into 2 types: HSS saw blades and TCT saw blades.

- HSS Saw Blade: The HSS saw blades are mainly made from M2 or M35, the material is heat and wear-resistant and is versatile to cut ferrous and non-ferrous metals.

- TCT Saw Blade: The TCT saw blades consist of a steel blade body with tungsten carbide tips brazed onto the blade teeth. They are more durable and efficient than HSS saw blades, so their cost is higher than HSS blades.

Tooth Configuration

When talking about tooth configuration, we can talk from 3 points: number of teeth, tooth geometry, and tooth pitch.

Number of Teeth

The number of teeth affects the smoothness and speed of the cut. If your blades have more teeth, you need to cut slower, but with smoother cutting ends. If your blade has fewer teeth, the cutting speed is generally faster, but the smooth is rougher.

Tooth Geometry

The shape and angle of the teeth influence the cutting action and chip removal.

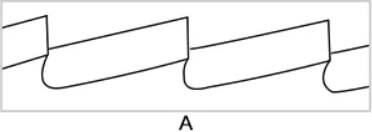

Tooth Form A

Used for non-ferrous cutting of thin-walled profiles.

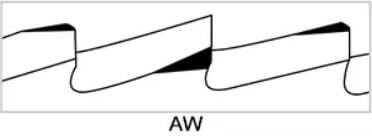

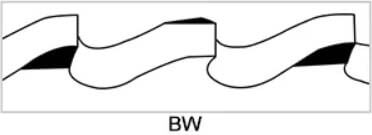

Tooth form A W

Used to cut thin-walled non-ferrous profiles or plastics.

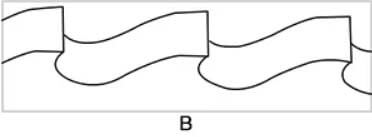

Tooth form B

Tooth form B is stronger than form A and AW, and it is used to cut non-ferrous materials and plastic materials.

Tooth form B W

Used to cut small-size profiles and workpieces, suitable for all materials.

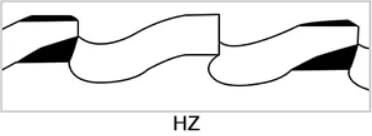

Tooth form C (HZ)

Used to cut large workpieces, the teeth are alternately beveled, this pattern helps to create a cleaner cut.

Whether you want to cut stainless, aluminum, brass, copper and plastic, above tooth form or special tooth form can be ground according to according to specific production needs. Here you can find the circular saw blade sharpener.

Tooth Pitch

The tooth pitch means the distance between the tips of the adjacent teeth on the saw blade, the distance determines how many teeth are in contact with the material being cut at any given time. The tooth pitch can be different according to different cutting materials, generally a smaller tooth pitch is used for cutting thin-walled or softer materials, and a larger tooth pitch is used for cutting thicker or harder materials.

Blade Coating and Finish

The coating of a cold saw blade can enhance its performance, the common coating includes:

- Titanium Nitride (TiN): The circular saw blade coating with titanium nitride can increase its hardness and wear resistance, generally used to cut thin wall tubes.

- Titanium Aluminum Nitride (TiAlN): Titanium Aluminum Nitride can provide a very hard surface, suitable for cutting the stainless steel and titanium alloys. This coating is also highly resistant to high temperatures.

- Black Oxide Coating: This coating is the most common coating for metal cutting circular saw blades. For any kind of cold cut saw blade, the coating is necessary to prevent galling.

- TiCN Coating: This coating is very wear-resistant and resists edge wear. It performs better than TiN when sawing stainless steel and other non-ferrous metals due to its lower temperature threshold.

Diameter and Thickness

The diameter and thickness of the circular saw blade for metal should match the cutting requirements.

- Diameter: Generally, a larger diameter is suitable for cutting the thicker materials, and a smaller diameter is suitable for cutting the thinner materials.

- Thickness: Thicker blades are more strong and stable during the cutting process. The thinner blades offer finer cuts, but the durability is not so good.

Cutting Material

When choosing the cold saw blade, you also need to refer to what materials you need to cut. For example, if you are going to cut harder materials, like stainless steel and hardened steel, we suggest you choose the blade with a higher tooth count. If you are going to cut the softer material, like aluminum and copper, we suggest you choose the blade with a lower tooth count.

Choosing the Right Cold Saw Blade for Specific Cutting Material

Let’s take a look at which metal circular saw blade performs well for specific cutting material.

Steel Tube Cutting

It is better to choose the HSS or TCT saw blade with TiN or TiAlN coating to cut the mild steel tube. When cutting the thicker and harder steel tube, you need to use the metal cutting blade for a circular saw with fewer teeth. Likewise, when cutting the thinner and softer material, you need to use the circular saw metal cutting blade with more teeth.

Cast Iron Tube Cutting

For cutting the cast iron tube, you can choose to use TCT saw blade with TiN or diamond coatings. For the tooth form, we suggest to choose flat-top or alternate bevel teeth with fewer teeth amount, due to the cast iron is brittle.

Aluminum Tube Cutting

For cutting aluminum tube, we suggest using TCT saw blade with a non-stick coating. It is better to use alternate bevel teeth with a moderate number of teeth to cut aluminum tube.

Brass Tube Cutting

Cutting brass tube is also suitable for using TCT saw blades with non-stick coating. It is suitable to use alternate bevel teeth or triple chip grind (TCG) with a higher tooth count to effectively reduce the burr.

Stainless Steel Tube Cutting

Both HSS and TCT saw blades can be used to cut stainless steel tube, the appropriate coating should be TiAlN or diamond coatings. To cut stainless steel tube, we suggest using fewer teeth.

Ok, want to choose the best circular saw blade is complicated and not so easy. Different materials need to use different saw blades. Even with the same material, but different sizes, the configuration of the saw blade will vary. If you want to choose the most cost-effective circular saw blades for metal, contact TubeBenderN to provide the best solution for you!

How to Maintain the Saw Blade?

Here we will talk about the maintenance of saw blades from 2 aspects: during production and after production.

Maintain the Saw Blade During Cutting Process

- Match the Blade to the Material: Choose the appropriate blade type and configuration for the cutting material to minimize wear and tear.

- Correct Speed and Feed Rate: Cutting too fast or too slow will lead the damage to the cold cut saw blade, you’d better follow the advice of your supplier.

- Secure the Workpiece: Ensure the workpiece is securely held on the tube cutting machine to avoid movement during the process. If the blade moves during cutting, it will damage fast.

- Avoid Overheating: Overheating will reduce the hardness and lifespan of the circular saw blades for cutting metal, use cutting fluids or air cooling to manage the temperature.

Maintain the Saw Blade After Cutting Process

- Inspect Before Use: Before every use, you need to check if any signs of damage.

- Clean the Blade: You can use a soft brush and mild detergent to clean the blade. For tougher residues, use a specialized saw blade cleaner.

- Sharpen the Blade: You can regularly sharpen the blade to maintain cutting efficiency and precision. Looking for circular blade sharpening machine? Ask TubeBenderN!

FAQs about Cold Saw Blade

Q: How many teeth does a cold saw blade have?

A: The tooth number of a metal blade for circular saw can be customized according to different cutting materials. Generally, the metal cutting circular saw blades have 60-120 teeth.

Q: What is the rotation speed of cold saw blade?

A: The RPM also needs to refer to specific cutting material and cutting size, the common RPM for metal tube and pipe is 700-1500.

Q: How to sharpen a circular saw blade?

A: We suggest using the saw blade sharpener to sharpen the saw blade.

Q: Why does my circular saw metal blade wear out so easily?

A: There are too many factors that cause this problem, maybe the saw blade type does not fit the cutting material, or maybe the cutting speed is incorrect. Click here to ask our expert!

Q: Is there one type of saw blade suitable for cutting all metal tubes and pipes?

A: Yes, there are versatile saw blades to cut different metal tubes, please consult with our expert!

TubeBenderN is a manufacturer of tube cutting machine, saw blade, and sawblade sharpener manufacturer in China. If you are looking for the best circular saw blades used to cut metal tubes and pipes or related equipment, you’ve come to the right place. Contact us Today to get the best tube-cutting solutions!

You may also interested in:

Denis Lau

Denis Lau has 20 years of work experience in the metal processing industry. His major in university was mechanical engineering, and after graduation, he started from the bottom of the workshop, gaining extensive hands-on professional experience and the ability to tackle challenges from various industries.