Mandrel Pipe Bending

Normally, when bending the pipe, the mandrel will be used in the pipe bender to prevent common bending issues that happened during the bending process. The mandrel inside the pipe can prevent the pipe or tube from flattening and makes the steel pipe bends without any kinks and wrinkles.

Mandrel pipe bending is different with the pipe bender without mandrel, the mandrel pipe bender work begins from the tube being pulled over a mandrel which is held in a fixed position.

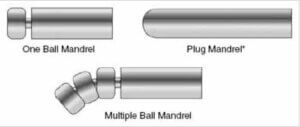

We are talking about two mandrels here: plug mandrel and ball mandrel.

When using a plug mandrel, the physical change of tube stretching is located on the outer radius of the pipe bends. For this type of bending, the material is work-hardened to maintain its shape, not flattening. The stretching of the material is done at the front end of the mandrel. The bending force acting on the tip of the mandrel supports the inner radius of the bent part and holds it to the bending die groove firmly.

For mandrel pipe bending, we normally require a ball mandrel and wiper die, the process is slightly different from above. The ball part of the ball mandrel inside the tube prevents the tube from collapsing, even when the bent part leaves the mandrel shaft. The wiper die, as all of us know, its function is to prevent the tube from wrinkling.

When customer requires tight bends or thin wall tubing bends, the wiper die is necessary. For thin wall tubing or tight bends, the pressure during compression is so intense, it is difficult to maintain the material without the help of a wiper die.

Contact us by email: info@tubebendern.com or Call/WhatsApp us at (0086) 1505 1715 426 or fill out the below form.