Electromechanical Tube Bending Machine vs Hydraulic Tube Bending Machine

Everyone knows that the 100% electric tube bending machine is the best industrial tube bending machines for all aspects. But, when your budgets are limited, you need to consider other types of tube bender machine to fit your production needs at lower cost.

Bending tube by electromechanical tube bending machine proceeds with the servo motor which makes the bending result in high accuracy with high efficiency.

Bending tube by hydraulic tube bending machine proceeds with the hydraulic cylinder which makes lower cost with wide bending tolerance.

Different types of tube bending machine fit different applications. Let’s take a look at the main features of the electromechanical tube bending machine:

- Economical-low purchase cost with high efficiency.

- Less quantity of cylinder-low maintenance cost.

- Quick die adjustment-multiple layers of die, change the tooling automatically.

- Strong-the machine is strong, but not so heavy, you can easily move the machine to where need it.

- Easy to use-more advanced machines are always programmed already and easy for workers to operate.

The features of the hydraulic tubing bending machine:

- Stable-large tube bending machines provide stable bending conditions and high bending precision.

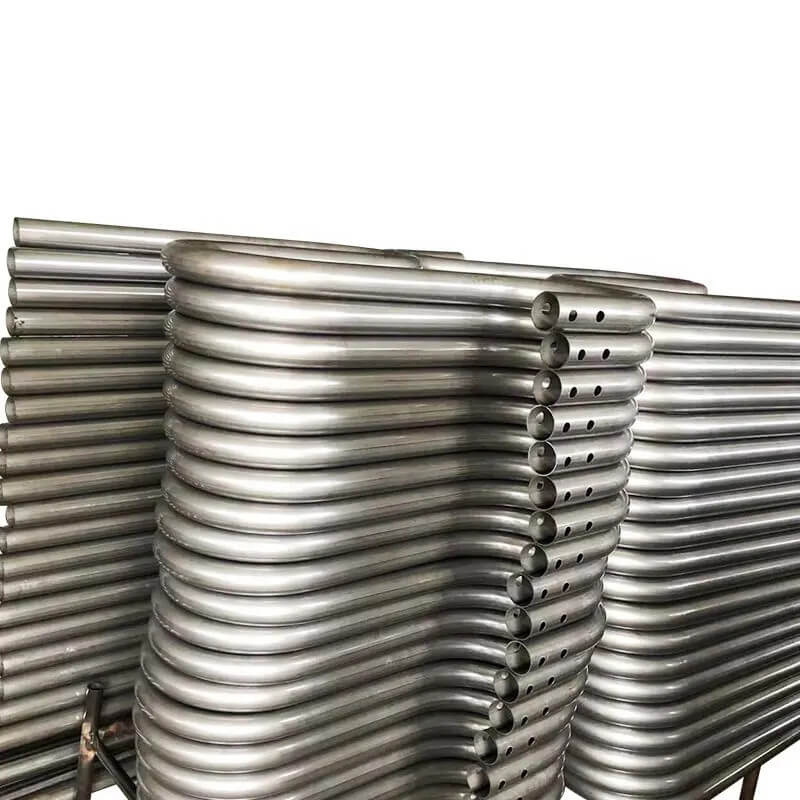

- More function-if your tube bending needs booster, hole punching function, these functions can be added to the machine.

- Bending radius can be less than 1.5D-this is depend on different tube bending designs, our tube bending equipment can produce a wide range of bending radii, some even less than 1.5D.

Knowing the features of different types of tube bending machine is very important, this is better for us to find the best solution to meet customer’s requests.