Complete Guide Before Purchasing CNC Tube Bending Machines

Are you going to buy a CNC tube bending machine for your production? How much do you know about CNC tube bending machines? If your budget is enough, we strongly recommend you purchase a CNC tube bender, instead of a semi-automatic, because they can reduce manual error and increase productivity. TubeBenderN produces tube bending machines from a single stack to multiple stacks, we provide different features from full hydraulic to full electrical servo motors tube bending machines.

Below we will guide you to know the most concerning points about CNC tube benders. If you have any questions or are interested in purchasing our machinery, please contact TubeBenderN through below contact information.

Single and Multiple Stack CNC Tube Benders

Single stack CNC tube bender is designed for simple bending projects but needs to keep the precise and consistent bending result. If you have more than one bends on the pipe with the same bending radius, the single-stack CNC tube bending machine will improve production efficiency.

Multiple stack CNC tube bender is designed for complicated tube bending projects and they are many bends with different bending radius on the tube, the machine will automatically change the bending tooling. The multiple-stack CNC tube bending machine provides a precise bending angle and consistent bending result without any human error.

Choosing which type of CNC tube bender depends on your production needs, if you are not sure, feel free to contact TubeBenderN, we will help you to find the best solution.

When is the best time to purchase CNC tube benders?

From our company’s sales experience, the second half of the year, especially the last quarter, is the best for machine sales. In many companies, they have to make the production and sales for next year and they may need a new machine for preparation, so most of them will choose to customize CNC tube bending machines or buy the CNC pipe bending machine for sale in the last quarter of the year. The machine may deliver at the end of the year or the beginning of the new year.

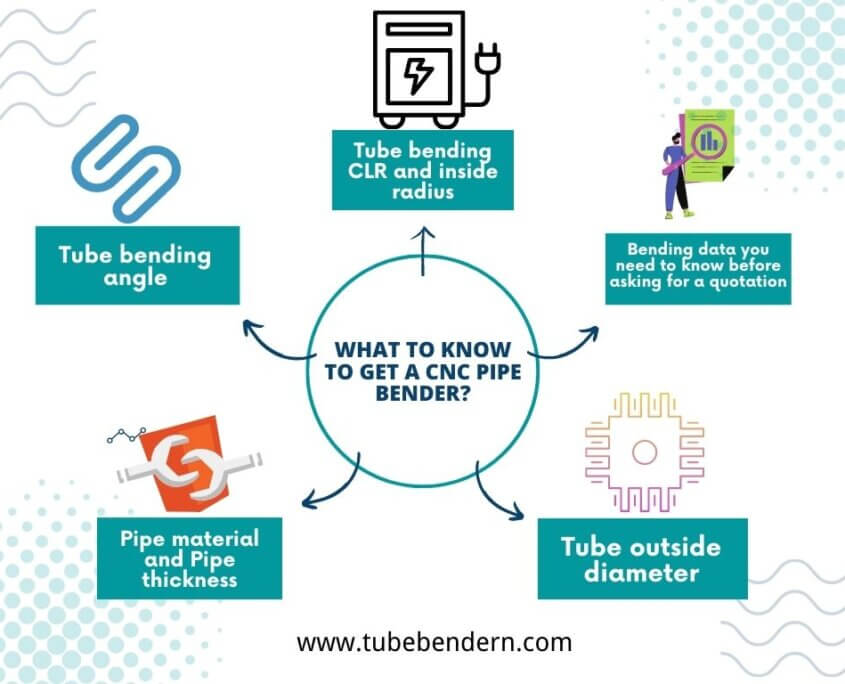

What to know to get a CNC pipe bender?

Purchasing CNC pipe bending machines is not a small project, so you can ask for a quotation and after you get a quote, you can calculate the cost to see if they can meet your budget. Sure, there are many factors that affect the machine quotation.

- Bending data you need to know before asking for a quotation

You need to collect all the bending data, such as pipe outer diameter, pipe thickness, pipe material, pipe bending radius, and bending accuracy. If possible, you need to prepare all the pipe drawings for the pipe bending machine manufacturer, this information will help them to make the exact quotation of the machine that fits your needs.

- Tube outside diameter

Tell the tube bending machine manufacturer your largest tube outside diameter, this will determine the bending machine model and the bending tooling. Due to some customers having different cognition of pipes and tubes, when we talk about the outside diameter of tubes or pipes, the size of the tube and pipe will have a little different. If you have a drawing, please provide it to the machine manufacturer to ensure the size.

- Pipe material and Pipe thickness

CNC pipe benders can bend different material types, such as stainless steel tubes, carbon steel tubes, copper tubes, aluminum tubes, titanium tubes, etc. Pipe wall thickness is also very important because this will determine how many balls of the mandrel will be used and the mandrel material.

- Tube bending angle

Knowing the tube bending angle is also very important, this will also determine the amount of balls in the mandrel, the bending angle also affects the tooling customization. If you ask the CNC tube bender for sale, they may have stock. But in most cases, the bending tooling needs to be customized according to your actual tube bending angle.

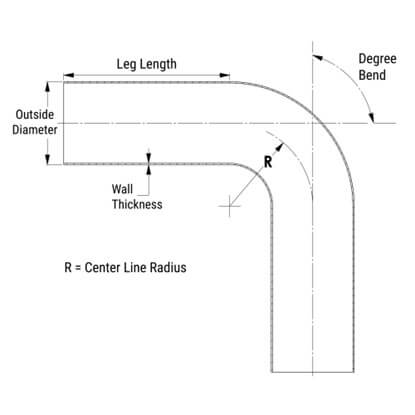

- Tube bending CLR and inside radius

The tube bending radius is very important to determine the bending die size of the tube bender. You should know how to measure the radii and please note, always there are 3 parameters of bending radius, they are the inside bending radius, the centerline radius, and the outside bending radius, you can see the below drawings for a better understanding.

If I don’t have pipe drawings and do not know pipe parameters, how can I buy a tube bending machine?

The answer should be: send your pipe or tube sample to the machine manufacturer and they will check all the parameters, then make the machine and tooling according to your sample.

This is also what we suggest customers do. Since we need to debug the machine for customers and make sure when customers receive our machinery, they can use it in a very easy way. As you know the same size, the material of the tube or pipe you order may be different from the same size and material we got from our supplier, so send your tube and pipe to use and let us debug your customized tube bending machine with your material, this will be 100% perfectly fit your production needs when you get our machine.