CNC Tube Bender Application

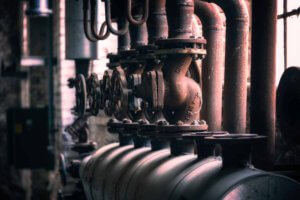

You can see a lot of tubes and pipes in different shapes in your daily life, almost all the industry regarding tube and pipe fabrication needs to bend. So, let us see some applications that our CNC tube bender serve for:

- Automotive industry

- Aerospace industry

- Shipbuilding industry

- Furniture industry

- Boiler and Power industry

And more!

Why use CNC Tube Benders?

Comparing with semi-auto tube bender, CNC tube bender has many advantages, such as bending accuracy, bending speed, bending efficiency, all these advantages could help you increase your productivity and profitability.

Bending Accuracy and Consistency

Bending accuracy and consistency is an important factor when your application requires high precision bending result and production volume is large. CNC mandrel tube benders are used to bend one more bending radius on the same pipe, you do not need to change different bending die when you need to bend different radius, since you can set the program in the computer and the machine head can change to different bending die to bend different angles, the whole process do not need the human working, so the result can keep the bending accuracy and consistency.

For example, the automotive parts, motorcycle parts, bus parts, racing car parts, requires high bending precision and consistency, large quantity, repeatable production, so they need high-end CNC tube benders, sometimes need to add extra functionality, like push bending, boost bending.

Bending Complexity

Nowadays, each industry requires complicated tech to improve product competitiveness. So they need complex bending more than simple. CNC tube bender can meet all the requirements of these industries which demand the complexity of bending technology.

CNC tube bender provides a precise bending result, high efficiency, and quick-change tooling, different bending radius on the same pipe. Since this is the custom-made pipe and tube fabrication machinery, so it has endless possibilities.