Choosing the Best Circular Saw Blade for Aluminum

Whether cutting aluminum tube, aluminum profile, or aluminum sheet, this is a very common task in various industries. Although the aluminum belongs to the metal, aluminum is softer than steel and harder than wood. If you use the circular saw blade for wood to cut the aluminum, the saw blade can easily become clogged, causing chip removal issues. If you use the circular saw blade for steel to cut aluminum, it is easy to cause the saw blade to overheat and heat up quickly, resulting in aluminum tube deformation, cut end burrs and uneven cuts, etc.

To ensure the quality of aluminum tube cutting, choosing the best circular saw blade for aluminum is very important. In this blog, we will explore the key features of aluminum cutting blades and provide guidance on how to choose the best one for your needs. You can also tell us your request, our expert will suggest the best solution for you!

About Aluminum Cutting

Aluminum is a widely used material due to its lightweight, high strength, and corrosion resistance. As a metal material, aluminum is quite different from steel, iron, stainless steel, and other metal materials. So, when choosing the aluminum cutting circular saw blade, you need to choose the right one according to its properties.

Aluminum Properties That Will Affect Cutting

Let’s take a look at what properties of aluminum affect its difference from other metals when choosing saw blades.

Softness

Aluminum is softer than other metals, you may think it is easy to cut, yes. But, it also means the aluminum chips can easily accumulate between the teeth of the saw blade. So, the circular saw blade for cutting aluminum should have specific tooth configurations and coatings to solve this issue.

Heat Generation

The cutting process of aluminum will generate significant heat, and the melting point of aluminum is low. So, this will lead to the deformation of the material and affect the cutting quality and cutting precision. To solve this problem, the aluminum circular saw blade should have heat-resistant coatings to ensure smoother and more accurate cuts.

Types of Aluminum for Cutting

- Sheets: Aluminum sheet is flat and thin, normally used in industrial applications. Generally speaking, the more teeth there are, the smoother the cutting edge. When cutting actual products, it is still necessary to make a specific analysis based on the actual size and specific situation.

- Extrusions: Aluminum extrusions can be in various shapes through the extrusion die, including tubes, angles, and channels. Choose the right aluminum cutting saw blade according to different cutting requirements and precision requirements.

- Castings: The saw blade used to cut aluminum castings must be sturdy, because the production of castings may contain impurities with varying thicknesses.

Key Features of a Qualified Circular Saw Blade for Aluminum

Selecting a qualified saw blade for aluminum cutting must consider below features:

Material

- Carbide Tip Circular Saw Blade or Specialized Non-Ferrous Metal Blades: The material of saw blades is very important when we choose our specific cutting materials. Generally, the material we choose for aluminum saw blades is carbide-tipped or specialized non-ferrous metals. The carbide tip circular saw blade is quite durable and the specialized non-ferrous metal blades can also be an ideal choice after being specifically designed.

Teeth Count

- Higher Teeth Count for Smoother Cuts: The teeth number of saw blade also affect the cutting quality. Generally, the more teeth there are, the smoother and cleaner the cut surface will be. The thinner the aluminum material, the more teeth the saw blade will have. The thicker the aluminum material, the fewer teeth the saw blade will have. The specific number of teeth on the aluminum saw blade you purchase depends on the specific situation, or you can consult our experts.

Tooth Geometry

- Triple-Chip Grind (TCG): The geometry of the teeth is another critical factor. According to industry experience, the saw blade with Triple-Chip Grind (TCG) tooth is the best choice for cutting aluminum. TCG blades alternate between a flat-topped raker tooth and a trapezoidal tooth, which helps distribute the cutting load evenly, reducing stress on each tooth. This design helps to ensure the cleaner cuts.

Blade Coating

- Coatings to Reduce Friction and Prevent Sticking: To improve the lifespan and efficiency of the circular saw blade, many aluminum cutting blades are coated with titanium nitride (TiN) or other heat-resistant materials. These coating materials can reduce friction between the blade and the aluminum, and prevent the material from sticking to the blade.

Types of Aluminum Saw Blade

On the market, you can see a variety of saw blades for cutting aluminum. When you use an inappropriate saw blade for cutting, it is damaged quickly and various problems will occur on the cutting surface of the cutting material. Here are the main 3 types of circular saw blades used for cutting aluminum.

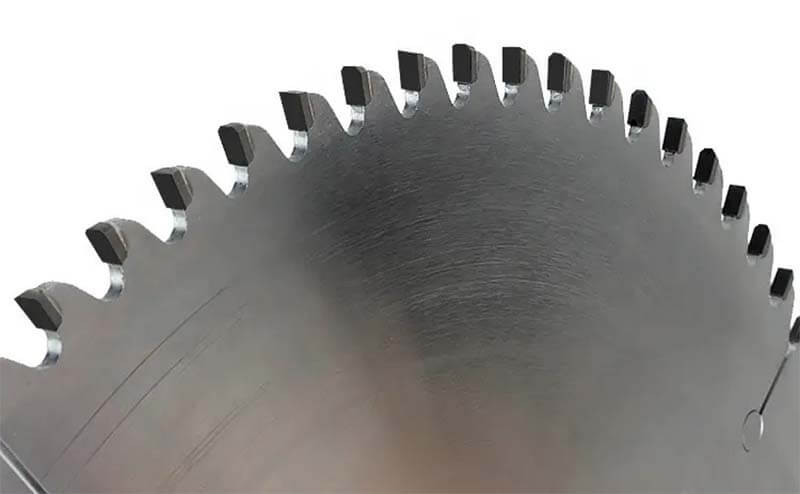

Standard Carbide-Tipped Blades

Compared to the steel blades, the standard carbide-tipped blades use the carbide-tipped teeth to improve the blade’s durability and sharpness. Carbide-tipped circular saw blades can be used to cut various materials, not only metal, but also wood, but their tooth shape and other configurations must be different. Consult with our expert to choose the best-fit saw blades for your material.

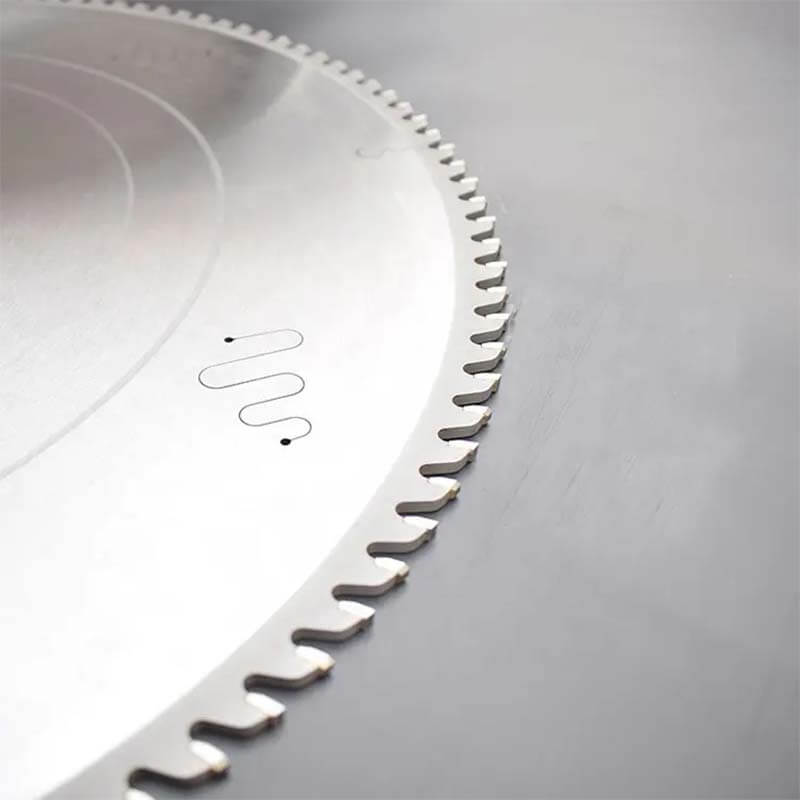

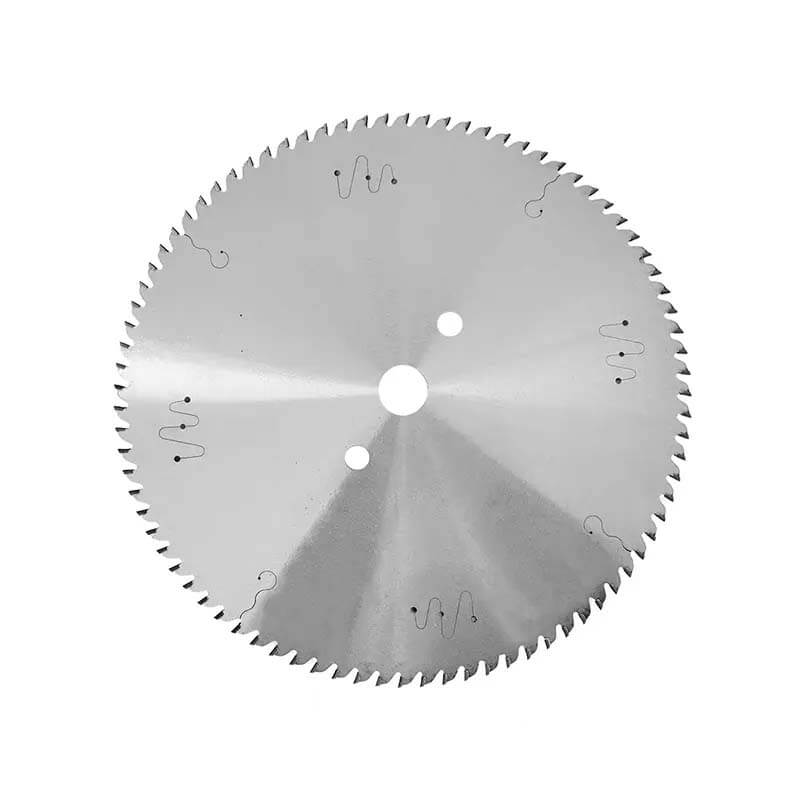

Non Ferrous Metal Circular Saw Blades

Non ferrous metal circular saw blades are the kind of cutting blades that are specifically designed for cutting aluminum copper and brass. These blades are designed with a triple-chip grind (TCG) tooth configuration and have a higher tooth count, suitable for cutting softer material and the cutting edge is smooth, aluminum chips will not easily clog the saw teeth and the saw blade will have a long service life.

Diamond Blades

The diamond blades are embedded with industrial-grade diamonds on the cutting edge, they have excellent durability and sharpness. Using this type to cutting aluminum in large quantities will maintain the cutting quality and efficiency. But, the price of diamond blades is high.

How to Choose the Right Saw Blade for Aluminum Cutting?

Choosing the proper saw blade for aluminum cutting should consider the below factors. Please note, that the selection needs to consider multiple factors according to the actual situation.

Saw Compatibility

- Make sure the circular saw blade size can match your circular saw machine’s specifications. The common sizes include 7-1/4 inches, 10 inches, and 12 inches, but you should check the saw manual or ask your saw supplier.

- The arbor size should also match the blade’s arbor hole. Using improper size will lead to unsafe operation and poor cutting performance.

Cutting Speed and Precision

- The tooth count and tooth geometry of the blade significantly impact cutting speed and quality. Generally, the saw blade with a higher tooth count can cut smoother but with a slower cutting speed. Conversely, the blades with fewer teeth can cut faster but the cutting edge is rough. The tooth count is based on the cutting material size, consult with our expert to get the proper saw blade.

- The non-ferrous metal blades have a higher tooth count and the triple-chip grind (TCG) tooth can balance the speed and precision and a cleaner cuts.

Maintenance and Safety Tips

Regular maintenance of circular saw blades is important to ensure optimal cutting performance. In addition, follow precautions to ensure personal safety.

Blade Cleaning

Regularly clean the aluminum chips from the blade to prevent the blade from clogging, dulling, and heat buildup during production. Use a soft brush and mild detergent or water to clean the blade and wipe it completely dry before reinstalling. Be careful not to use sharp materials or harsh chemicals to damage the blade or its coating.

Blade Sharpening

Regular inspection is a very important action to know when need to sharpen the saw blade. If you find increased resistance during cutting, rough or uneven cuts, and excessive heat generation, you need to sharpen the blade now. Need saw blade sharpening machine? Ask TubeBenderN! If the blade still does not work well after sharpening, then you need to replace it.

Please pay attention when you cut the aluminum with a circular saw blade, you need to wear safety glasses, hearing protection, gloves, and a dust mask, to protect against flying debris, noise, and dust.

When you choose the circular saw for aluminum, it needs to be based on what type of aluminum you are cutting. Even the same type, you need to consider the cutting material thickness, cutting request from clients, cutting speed, and cutting machine that needs to be compatible.

TubeBenderN is the manufacturer of various circular saw blades in China. If you want to buy saw blades for your production or wholesale round saw blades for your business, contact us today to get your best aluminum-cutting solution!

You may also interested in:

The basics of circular saw blade for metal

Denis Lau

Denis Lau has 20 years of work experience in the metal processing industry. His major in university was mechanical engineering, and after graduation, he started from the bottom of the workshop, gaining extensive hands-on professional experience and the ability to tackle challenges from various industries.