All You Wanted to Know About Mandrel Pipe Bender

As a leading manufacturer in the tube fabrication machinery industry, TubeBenderN are dedicated to producing high-quality machinery that meets the needs of our customers. Our mandrel pipe benders are designed to offer precision, efficiency, and versatility in tube fabrication, making them ideal for a wide range of applications. In this blog, you will get all you wanted to know about mandrel pipe benders, let’s discover now!

What is A Mandrel Pipe Bender?

A mandrel pipe bender is a highly specialized machine that employs an internal support mechanism, known as a mandrel, to achieve exceptional precision and accuracy in bending pipes while maintaining their structural integrity. The mandrel plays a crucial role in preventing deformation and ensuring the pipe retains its original shape throughout the bending process.

When bending a pipe without the assistance of a mandrel, the tube becomes vulnerable to collapse or distortion, resulting in issues such as ovality, wrinkles, or thinning of the pipe wall. By incorporating a mandrel into the process, these undesirable effects can be effectively prevented. The mandrel provides essential internal support that reinforces the pipe during bending operations and ensures a smooth and consistent bend while maintaining its structural integrity.

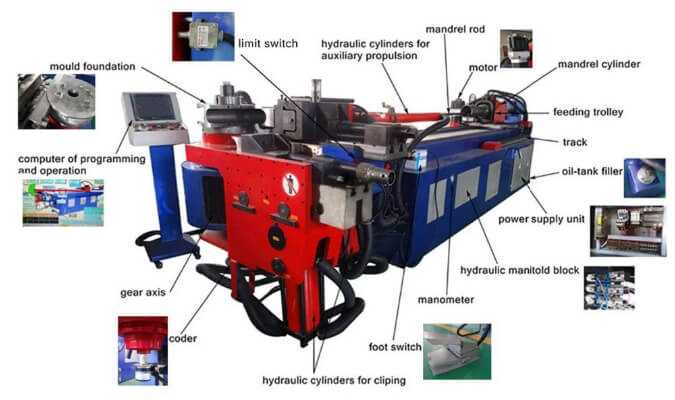

The mandrel pipe bending machine consists of several key components that work together to achieve efficient and high-quality bends. These components include the bender head, mandrel, clamping dies, pressure die, hydraulic system, and control panel.

- Bender Head: the key component of a pipe bending machine responsible for executing precise and accurate bends by securely holding the pipe in place and applying necessary force.

- Mandrel: a tool inserted inside the pipe to maintain its shape during bending.

- Clamping Dies: used to secure the pipe in place during bending. They hold the pipe firmly to prevent movement or slippage during the bending process.

- Pressure Die: exerts force on the exterior of the pipe, counteracting any buckling or distortion that may occur.

- Hydraulic System: the mandrel pipe bending machine is powered by a hydraulic system, which provides precise and controlled force and movement for the bending operation. This ensures accurate and consistent bending while allowing flexibility in adjusting parameters.

- Control Panel: allows operators to set specific bending parameters, such as the desired bend angle, radius, and speed. Operators can monitor and adjust the bending process through the control panel, ensuring optimal results.

How Mandrel Bender Works?

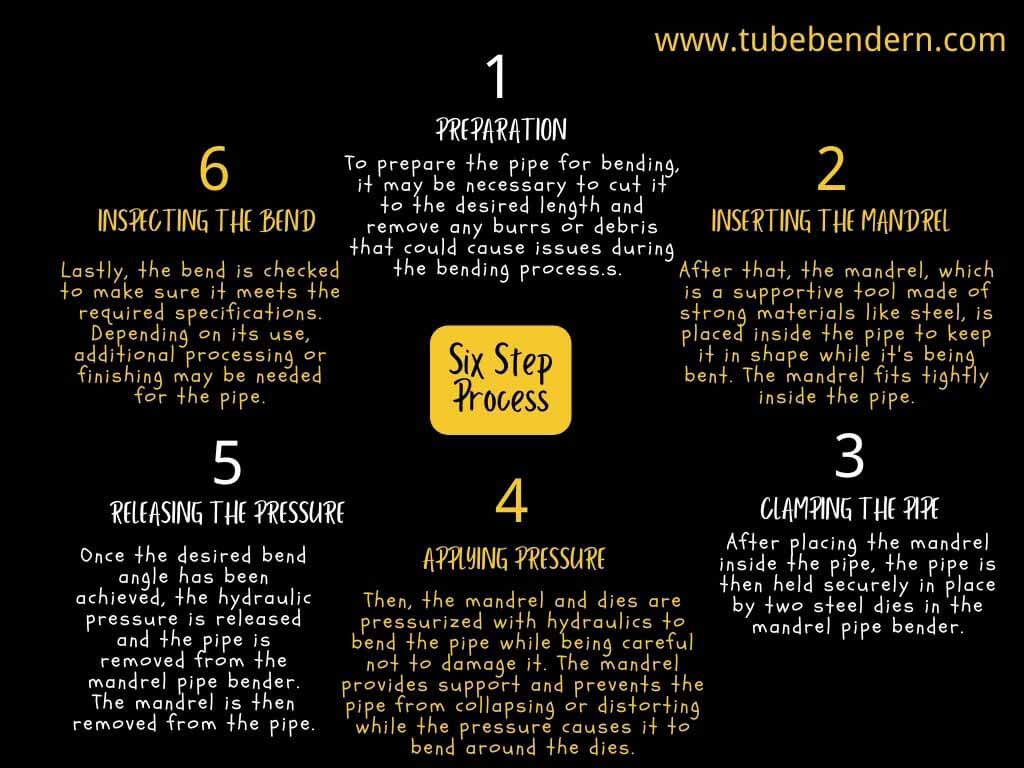

Mandrel bending is a method used to bend pipes or tubing without causing any deformations or wrinkles on the inner radius of the bend. This technique is commonly used in the automotive, aerospace, and construction industries, as well as in the manufacture of exhaust systems and furniture.

The process of mandrel bending involves inserting a mandrel, which is a solid metal rod, inside the pipe or tubing that needs to be bent. The mandrel is placed at the inner radius of the bend, and it supports the pipe or tubing from the inside, preventing it from collapsing or wrinkling during the bending process. The mandrel is usually made of steel, and it is available in various sizes and shapes to accommodate different pipe and tubing diameters and bend radii.

Look at below flow chart of how does a mandrel bender work, you will have a clear view.

The Comparison in Different Types of Pipe Bender

| Type of Pipe Bender | Advantages | Disadvantages | Rating (1-5)* |

| Manual Pipe Bender | – Inexpensive – Portable – Simple to operate | – Limited bending capacity – Labor-intensive – Less precise | 2 |

| Rotary Draw Bender | – Precise and repeatable bends – Can handle large and thick-walled pipes – Can be automated for high-volume production | – Expensive – Requires skilled operator – Not portable | 4 |

| Compression Bender | – Can handle larger diameter pipes – Less expensive than rotary draw benders – Can produce multiple bends in one pass | – Less precise than rotary draw benders – More difficult to use than manual benders – Can leave marks on pipe surface | 3 |

| Mandrel Pipe Bender | – Can produce precise and consistent bends – Helps prevent wrinkling or collapsing of pipe during bending – Can handle a wide range of materials and wall thicknesses – Quick setup time and tooling change over time in CNC type | – Cost will be higher than other types of small equipment | 5 |

*Rating scale: 1 = poor, 2 = fair, 3 = good, 4 = very good, 5 = excellent

The Advantages of Our Mandrel Pipe Bender

- Unmatched Precision and Accuracy: Our mandrel pipe bender stands out by delivering superior precision and accuracy compared to alternative bending methods. The use of a mandrel guarantees consistent and accurate bends, allowing for precise angles with minimal variation.

- Enhanced Efficiency: With our mandrel tube bender, you can expect rapid and efficient bending operations, leading to time savings and increased productivity. Due to their high level of automation, these machines minimize the need for manual labor and are exceptionally user-friendly.

- Remarkable Versatility: Our mandrel benders excel in versatility, capable of bending tubes of varying sizes and shapes. This adaptability makes them an ideal solution for a wide range of applications, as they can handle different materials such as steel, aluminum, copper, stainless steel, and titanium alloy, catering to diverse industries.

- Cost-Effective Solution: Our tubing mandrel bender offers a cost-effective approach to tube fabrication and manufacturing. By providing high precision and accuracy, it reduces the need for rework and enhances productivity. Moreover, these machines require minimal maintenance and boast an extended lifespan, making them a smart and cost-effective investment for businesses.

- Reduced Waste: Our mandrel bending machine ensures minimal distortion and scrap, effectively reducing waste and optimizing production efficiency.

- Superior Quality: Our pipe mandrel bender consistently delivers reliable and consistent bends, ensuring that parts consistently meet the required quality and performance standards, ultimately enhancing the overall quality of the end product.

What Kind of Material Can Be Bent on Mandrel Tube Benders?

Our mandrel tube benders are designed to bend different materials: such as steel tube, aluminum tube, copper tube, stainless steel tube, and titanium alloy tube. The capacity and bending capabilities of the machine are affected by factors like tube thickness and tube hardness. Not sure which type and capacity of machinery can fit your specific needs? we recommend you consult with our experts. They can provide valuable guidance and help you make a correct decision.

How to Choose the Right Mandrel Pipe Bender?

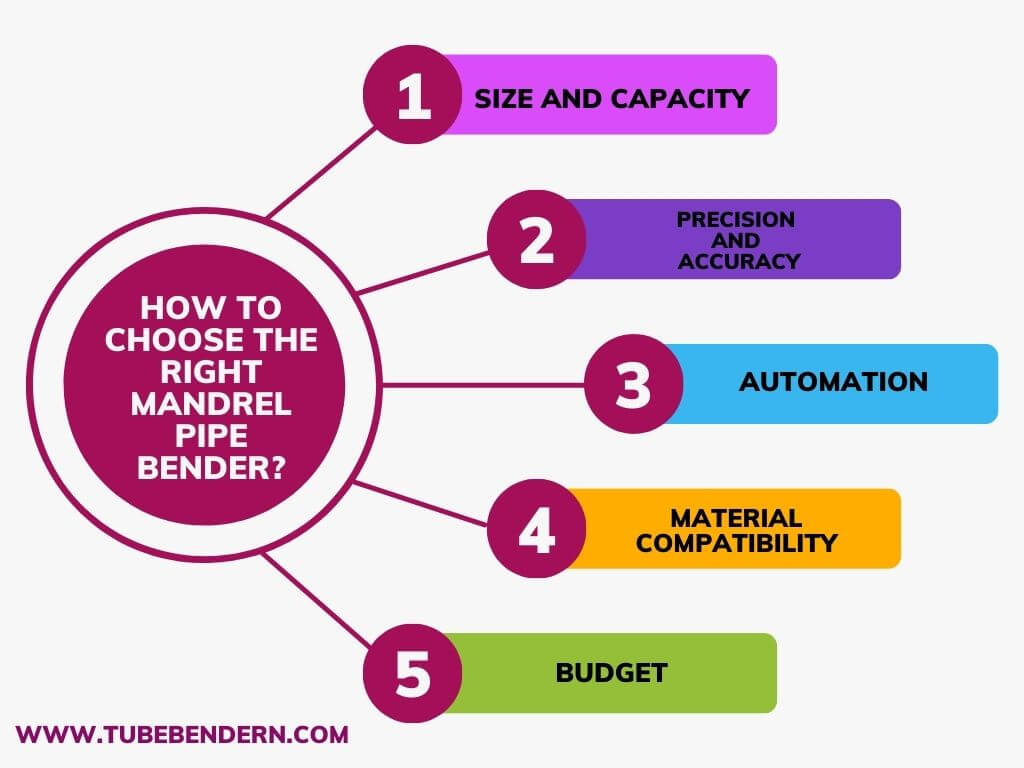

Choosing the right mandrel pipe bender can be a daunting task, but we are here to help. Here are some factors to consider before purchasing:

- Size and Capacity – When selecting a mandrel tube bender, the size and capacity of the machine is very important. It’s essential to choose a machine that can effectively handle the size and thickness of the tubes you intend to bend. Ensuring a proper match between the machine’s capabilities and your bending requirements will result in efficient and accurate tube bending.

- Precision and Accuracy – Precision and accuracy are crucial in tube fabrication. You should choose a tubing mandrel bender that can produce bends at precise angles with minimal variation.

- Automation – When evaluating a mandrel bending machine, the level of automation it offers is a key consideration. Opting for a machine that features a high degree of automation brings several advantages. It should be user-friendly, with intuitive controls and an interface that simplifies operation. By reducing the need for extensive manual labor, automation enhances productivity and minimizes the risk of errors. An automated mandrel bender streamlines the bending process, allowing operators to focus on other critical tasks while enjoying increased efficiency.

- Material Compatibility – Different mandrel pipe benders are designed to handle different materials. Some type can bend multiple tube materials, some type only can bend single tube material. You can ask the pipe bending machine manufacturer to choose a machine that can bend the tube material you plan to use in your own production.

- Budget – Tube bending machines come in different price ranges. You should choose a machine that fits within your budget while still meeting your requirements for precision, accuracy, and efficiency.

The Benefits for Different Applications

Our mandrel tube bender is suitable for a wide range of applications across different industries. Here are some examples of how our machinery can benefit different applications:

- Automotive Industry – The automotive industry requires mandrel tube bending a lot to manufacture exhaust systems, suspension systems, roll cages, and other components. Our mandrel exhaust pipe bender offers precise and accurate bending capabilities, making it ideal for producing high-quality parts with complex shapes and designs.

- Aerospace Industry – The aerospace industry requires precision and accuracy in manufacturing parts and components for aircraft. Our mandrel pipe bending machine offers tight tolerance bending and consistent quality, ensuring that parts meet the industry’s rigorous standards.

- Construction Industry – Our mandrel bender machine is used in the construction industry to produce tubes for scaffolding, handrails, and other structures. These tubes require high precision and accuracy to ensure 100% assemblability.

- Furniture Industry – Our mandrel bending machine is also used in the furniture industry to produce tubing for chairs, tables, and other furniture pieces. The precision and accuracy of our machinery ensure the complex furniture designs with multiple bends and shapes.

- Agricultural Industry – The agricultural industry uses tube bending to produce parts for farming equipment and irrigation systems. Our mandrel bender offers accurate and precise bending capabilities, allowing to produce high-quality parts to meet your final production needs.

- Medical Industry – Our bending machine offers precise and consistent bending capabilities, ensuring that the tube parts you produced meet your industry’s strict standards. Depending on the different products you produced, some parts can be produced by NC hydraulic pipe bender, and some parts need to be produced by CNC bender machine.

- Energy Industry – The energy industry uses tube bending for producing pipelines, heat exchangers, and other components. Our state-of-the-art tube bending equipment provides precise and accurate bends with a high level of consistency, guaranteeing that parts meet the exacting demands of the industry’s standards.

- Marine Industry – Tube bending plays a significant role in manufacturing components for boats and ships, including handrails, exhaust systems, and hydraulic tubing. Our mandrel bending machine is designed specifically for the marine industry, providing high-quality bending with minimal distortion and waste. By using our mandrel bender, marine manufacturers can confidently meet industry standards, enhancing safety, functionality, and performance in the marine sector.

- Sports Equipment Industry – The sports equipment industry uses tube bending for producing bicycle frames, exercise equipment, and other components. With the use of a mandrel, our pipe bending machine delivers top-notch bends with exceptional dimensional accuracy and tolerances, guaranteeing that parts conform to the most demanding industry standards.

- Electronics Industry – Tube bending is essential for producing components in the electronics industry, including computers, servers, and electronic devices. Our specially designed mandrel tube bender delivers accurate and precise result, manufacturers in the electronics industry can rely on our machine’s consistent precision and reliability to meet industry standards.

Where to Buy Mandrel Pipe Bender?

TubeBenderN is a pipe bending machine manufacturer. Our mandrel pipe bender is designed to provide exceptional precision and accuracy in tube fabrication. The machine uses a mandrel to hold the inner surface of the tube throughout the bending operation, preventing wrinkling or collapsing. Our machinery is completely customizable and can be designed according to your unique needs.

You can check more information about tube bending.

Denis Lau

Denis Lau has 20 years of work experience in the metal processing industry. His major in university was mechanical engineering, and after graduation, he started from the bottom of the workshop, gaining extensive hands-on professional experience and the ability to tackle challenges from various industries.