A Comprehensive Guide for Wheelbarrow Manufacturers

What is A Wheelbarrow?

Wheelbarrow is a small load-bearing vehicle that is normally designed with a single wheel, two supporting legs, two handles, and a cart. It is widely used for construction, agriculture, landscaping, and more.

The Benefits of Using Wheelbarrows

No matter whether you are moving soil, plants, or garbage, using a wheelbarrow to help you will benefit a lot.

Efficiency: By replacing moving loads by hand, using the wheelbarrow to move heavy loads will improve your working efficiency.

Versatility: Wheelbarrows are versatile tooling for various applications, you can use them for construction, landscaping, gardening, agriculture, and household chores.

Minimize Burden: You can distribute the load’s weight by using a wheelbarrow while transporting the loads.

Mobility: You may need to transport the loads over a long distance and unload them at different points, using a wheelbarrow will make it easier for you to transport these loads to different places, even if you need to navigate through uneven ground, narrow pathways, and tight spaces.

Cost Effective: Compared to other loads-moving vehicles, wheelbarrows are not expensive, easy to maintain, and can meet your needs for material handling.

Eco-Friendly: Using a wheelbarrow does not need fuel or electricity to start, so this is a 100% eco-friendly material handling tool, that does not have carbon emissions and energy consumption.

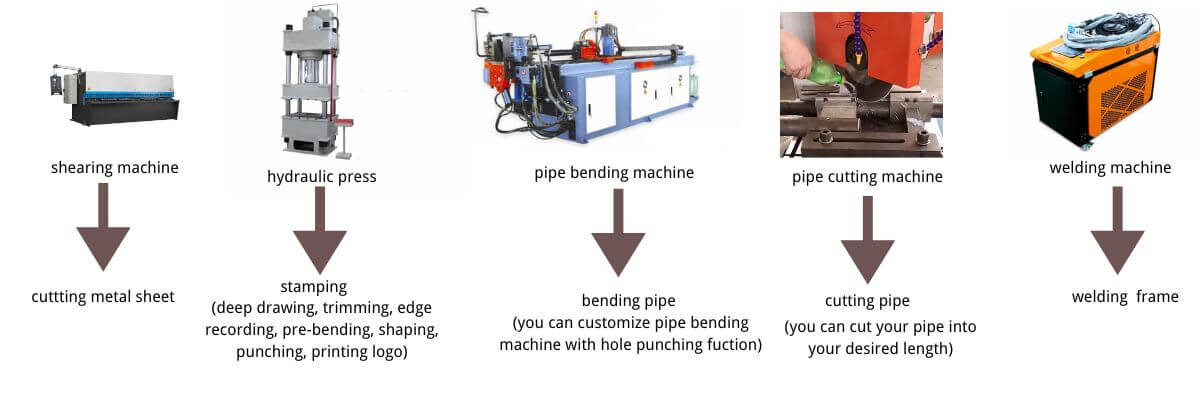

The Machinery Required for Producing Wheelbarrows

To produce high-quality wheelbarrows, you need to choose the right machinery and equipment. Here are the key machineries that are commonly used in wheelbarrow manufacturing.

Metal Cutting Machine: These include shearing machines, plasma cutters, and laser cutters for precise cutting of metal sheets used in frame and tray fabrication.

Pipe Bender Machine: Pipe bender machine is used to bend the metal pipe, and make the handles and frames of the wheelbarrow.

Understand more parameters and features of the pipe bender machine.

Cutting Pipe Machine: About pipe cutting, we recommend using CNC pipe cutter to cut the metal pipe to your desired length to ensure consistency in component production.

Understand more features of pipe cutting machine.

Welding Machine: Arc welding, MIG (Metal Inert Gas), or TIG (Tungsten Inert Gas) welding equipment, using which type of welding equipment to join frame components and attach handles need to according to your production request.

Press Brake: This machine is used to bend the metal sheet to make the trays of the wheelbarrow. If you already have a hydraulic press in the company, then you don’t have to buy a new press brake.

Powder Coating Equipment: Powder booths and curing ovens are used to create a protective surface with the desired color for the wheelbarrow.

Quality Control Tools: Instruments like calipers, micrometers, and weld inspection tools are essential for ensuring product quality.

What Needs to Consider Before Choosing the Machinery?

Production Capacity: No matter for bending the metal sheet, bending pipe, or cutting pipe, you need to choose the machine capacity that matches your production volume.

Accuracy: Different market requests and different types of wheelbarrows will affect the production accuracy. For example, the CNC pipe bender provides more accurate pipe bending results than the NC pipe bender.

Budget: Invest in equipment that offers the best balance of quality and affordability. Also need to consider if this machine is easy to operate, easy to maintain, etc.

Future Expansion: Consider your long-term plans and do you need these machines to accommodate your future growth production volume.

How to Produce Wheelbarrows?

There are different types, different sizes, and different colors of wheelbarrows in the market, but their production process is similar.

Design and Planning: Design the wheelbarrows, considering their load capacity, material, and ergonomics. Make the drawing for each component and assemble wheelbarrows.

Material Procurement: Sourcing high-quality materials, such as metal pipes, metal sheets, and wheels.

Machining: Using the specialized machinery to bend, cut, and punch the materials, forming each component ready to assemble.

Welding and Assembling: Weld the frame components together, ensuring sturdy construction. Assemble the wheel, axle, and handles onto the frame. Pay attention to alignment and symmetry.

Painting: Paint the protective coating on the surface of the wheelbarrow.

Quality Control: Using the quality control tooling to inspect the defects of the wheelbarrow. For inspection standards, you need to refer to the confirmed drawing or contract.

Packing: A well-designed packing solution will protect the wheelbarrow during transportation, save cost, and avoid wastage.

Common Material Types for Wheelbarrow Components

For each component of the wheelbarrow, there will be several types of materials in the market. Here are some common types of materials for your reference before procurement.

Frame Materials

- Steel: Steel frames provide strength and durability, an ideal choice for making heavy-duty wheelbarrows.

- Aluminum: Aluminum frames are suitable for making light-duty wheelbarrows, aluminum material is corrosion-resistant.

Tray Materials

- Polyethylene: This plastic features lightweight, and corrosion-resistant, making it an ideal material for the tray.

- Metal: Steel, aluminum, or other metal materials can be used to produce heavy-duty wheelbarrow trays.

Handles

- Wood: General wheelbarrow can choose wooden material to make the handle as a traditional type.

- Metal: For handling heavy loads, you need to use the metal handles as a strong support.

Wheel and Tire

- Pneumatic Tires: These tires are suitable for rough terrain.

- Solid Rubber Tires: These tires are durable and puncture-resistant, suitable for industrial use, like construction sites.

Common Types of Wheelbarrows in the Market

Wheelbarrow’s types are updated according to different market needs, let us have a look at what are the common types in the market these days.

Traditional Wheelbarrows

Traditional wheelbarrows feature a single wheel at the front, two handles, and an open tray for carrying loads. This type is versatile for a wide range of tasks, but be careful not to use it to carry too heavy loads since it is easy to tip over under heavy loads.

Heavy Duty Wheelbarrows

This type is designed for carrying heavy loads with a sturdier frame, reinforced handles, and a deeper tray, suitable for use in the construction site.

Folding Wheelbarrows

This type is mainly designed for homeowners with limited space. They are foldable, easy to transport and store, an ideal tool for gardening and other light duty task.

Two-Wheel Wheelbarrows

This type is upgraded from single-wheel to two-wheel to add stability to the wheelbarrow. They are easy to carry heavy loads over uneven terrain and reduce the risks of tipping over, making them popular for gardening and landscaping.

Motorized Wheelbarrows

This type of wheelbarrow also can be called an electric wheelbarrow, equipped with an engine. Suitable for transporting heavy loads over a long distance or up inclines, reduces the physical strain on users.

Are you planning to produce the wheelbarrow? Or looking for one of the machinery to produce the wheelbarrow component? Contact TubeBenderN to get the best solution.

Denis Lau

Denis Lau has 20 years of work experience in the metal processing industry. His major in university was mechanical engineering, and after graduation, he started from the bottom of the workshop, gaining extensive hands-on professional experience and the ability to tackle challenges from various industries.