8 Reasons for Why All-Electric Tube Bending Machine is Worth Investing in

With the improvement of production efficiency and quality control requirements, automatic tube bending machines will gradually replace semi-automatic tube bending machines sooner or later. CNC tube bending machines are widely used in automotive, aerospace, agricultural machinery, furniture, Naval and offshore, boiler and power plants, chemical industry, etc.

There are various kinds of tube bending machine on the market, as you see the manual tube bending machine, like a very simple tool used in the construction site, is mainly for bending the tube in less quantity and don’t have high bending accuracy request. But, an automatic tube bending machine is used for precise tube bending in mass production and the CNC tube bending machine has two main types: hydraulic tube bending machine and all-electric tube bending machine.

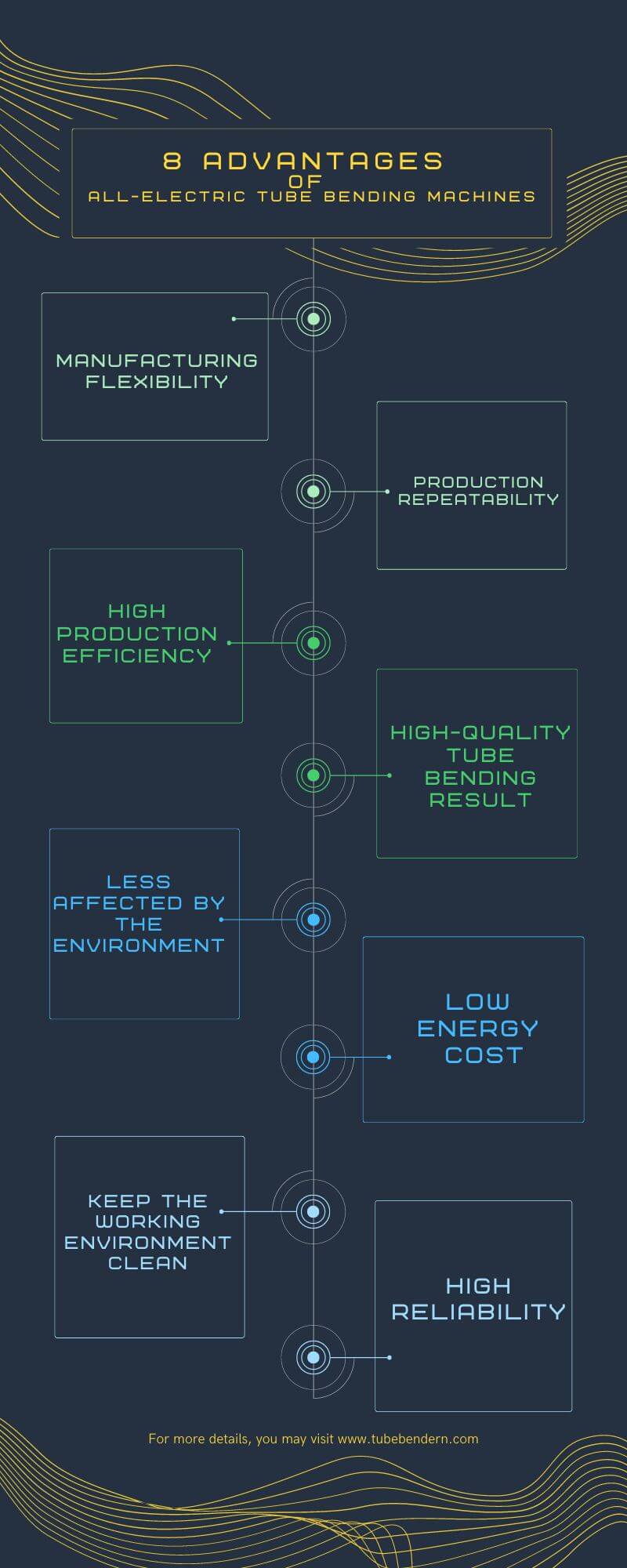

In this blog, we are going to talk about 8 advantages of all-electric tube bending machines. They are:

Manufacturing Flexibility

Nowadays, all the application requires high technology and production customization, so the simple and traditional tube bending machine can not exactly meet the client’s production demand. So, the market creates make-to-order production requests leads us to improve the flexibility in building the machine and production program. Especially for complicated tube bending, there must be not only machine tools, so production flexibility needs to ensure the machine tooling can be changed automatically and rapidly.

If you need to bend different bending radii on one tube, then you need to change the bending die. In some cases, you need to adjust the clamp die, the clamp pressure, and even the position of the mandrel, all these actions can be done by the machine programming software which is already set in the all-electric tube bending machine.

Using a hydraulic tube bending machine, you need to adjust all these movements by the operator and this may cause error and safety issues, both for worker and machine.

Production Repeatability

About the production repeatability of the tube bending machines, we need to focus on bending accuracy and the repeat bending process.

Accuracy means the tube parts movement carried out by the machine electric axes. After one bent finished, the machine cart will take the tube to the next programmable position. But, as all of you know, because of the physical properties of steel tubes, the elongation and spring-back of the tube will occur during the bending process, so keeping the repeatability and bending angle consistency is very important to ensure the measurement of the mass production is accurate.

In the automotive and aerospace application, they are using the all-electric tube bending machine to replace other types of bending machines to make the tube parts production repeatability and less waste.

In the program of a microcomputer, the manufacturer has already set up the coordinate axis and tube bending parameters and by this, your produced parts can be repeated and repeated time after time with completely consistent accuracy. Unlike the hydraulic tube bending machine other manual tube benders, the fully electric CNC tube bending machine does not need to do any manual adjustment, once the tube bending parameter has been set up in the program, you can use it any time, even a few years later, you want to use the same bending program, you can find it in the microcomputer. Also, operating by the electric axes all the process will avoid the human error, you don’t even need very experienced workers, this is another way to help you save cost.

High Production Efficiency

Tube bending machines are required by the industrial application for mass production, so production efficiency is very important.

The movement of all-electric CNC tube benders is controlled by the CNC axis and production cycle time is quicker than operated by workers. Our fully electric left-handed and right-handed CNC tube bender is widely used in furniture element production.

High-Quality Tube Bending Result

Tube bending by the hydraulic tube bender is controlled by the oil pressure in the hydraulic circuit and this may keep the same clamping pressure during the whole bending process, no matter for the thin or thick tube and this will cause tube parts damaged in some cases.

The CNC electric tube bending machine controls the force by various axes for thick or thin steel tubes, for soft or hard steel tube material, adjust the force during the process. This improves the quality of the complete bent tubes and reduce wear and tear on machine parts. You can also bend copper and aluminum tubes on a fully electric controlled tube bending machine.

Less Affected by the Environment

If you have been working with the hydraulic tube bending machine, you must know the tube bending accuracy will be affected by the oil temperature. From the beginning of the day, when you start the machine, the oil in the machine is cold and till the end of the day, when you finish the working, the oil is hot, the oil temperature will affect the oil viscosity and the oil viscosity will affect the machine movement, the higher the viscosity of the oil, the slower the machine moves, so this can not keep the tube bending consistency.

You will need an experienced worker to stand by the machine and check the quality of the tubes and adjust manually. This is not the ideal state of high precision bending requirements.

Due to the electric drives and motors in the all-electric tube bending machine will not affect by the oil temperature, the tube bending result will keep the same, no matter how many steel tubes you need to bend and how long you need to bend.

Low Energy Cost

Energy resources and prices are becoming more and more expensive, all the manufacturers need to save energy costs. Energy consumption occurred on the all-electric tube bending machine is when only the machine movement is needed. If you do not start the production, your cost is ZERO.

Keep the Working Environment Clean

A clean working environment will save the cost of cleaning and keep safe while working. If you have a hydraulic tube bending machine in your factory, you must know it is hard to keep the machine clean and if the oil leaks from the hydraulic system, you will see the oil everywhere, on the machine, on the floor, is hard to keep clean.

The electric tube bending machine doesn’t need any oil. So, working with this machine will keep the environment very clean.

High Reliability

Due to the electric tube bending machine doesn’t have an oil system, the machine doesn’t need to change hydraulic system parts.

A fully electric tube bending machine is controlled by the axis and if any malfunction occurs, they can be sent to the manufacturer immediately and the engineer can help to solve it.

According to our experience working with our customer, the failure frequency of hydraulic pipe bending machine is much higher than that of electric pipe bending machine, that’s why making the fully electric CNC tube bending machine a high ROI project in most tube and pipe fabrication workshops and the related application.

TubeBenderN has been exporting the all-electric tube bending machine to European and American countries, such as the USA, UK, Poland, Germany, Russia, etc. They are mainly for steel furniture manufacturers, automotive parts manufacturers, metal products workshops, etc. Contact us with your detailed request, our engineering will help to find the best tube bending solution for you.