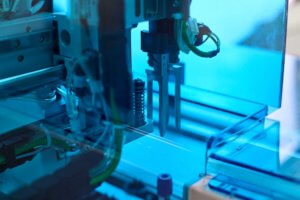

4 Aspects To Consider When Choosing The Right CNC Tubing Bender

Although we supply both semi-auto tube bender and fully automatic tubing bender to customers, we still highly recommend you to use an automatic bending machine to support your production, not only for now but also for your production in the future. As you can see, there are many types of bending machines on the market, even the same type CNC bending machine, you can find a wide range of models with a lot of parameters to choose from, so, we are going to 4 basic factors that you must consider while you are looking for CNC tube and pipe benders.

Automation

If you have enough cost to purchase tube and pipe benders and if you are a professional metal processing factory or professional tube and pipe fabrication factory, we highly recommend you to buy the automatic tubing bender, since buying machinery is not only for one time purposes, you still need the bending equipment to process more tube and pipe bending in the future. So, in a long run, the CNC tubing bender is the most worthwhile investment.

About the fully automatic tube bending machine, we have two types, one is an all-electric tube bending machine and another is a hybrid electric tube bending machine. The Hybrid Electric tube bending machine can meet most bending requests at a lower cost than the all-electric tube bending machine.

Power

When we talk about power related to CNC tube bending machines, it’s especially referring to the heavy industry, such as shipbuilding, trucking. You must choose the CNC tube bender that can perform the bending and we suggest you choose the machine model which has enough and additional power to handle this heavy-duty tube because we found there are some hostile competitors, they want to snatch customer’s order and quote a very low price to the customer and finally, customer get the tube bending machine in bad quality and not fit their production needs.

Precision

In some applications, they do not require very high precision, so sometimes, our semi-auto tube bender is enough for them to produce their pipe and tube parts. but in some other applications, they require extremely high precision, such as automotive and aerospace applications. Our hybrid electric tube bender can meet most of their precision requirements. If you are looking for more advanced CNC tubing bender, our all-electric must be your choice.

Complexity

Complexity is also a very important factor for you to decide which model of CNC benders you need to choose. complex bends are always going hand in hand with precise bends. The application requires high precision machining of pipe fittings are always tend to process high complexity pipe fitting.

One of our CNC tube bending machine – left and right hand CNC benders are very popular in the application that requires complex shapes tube bending. If you serve in tube and pipe fabrication for your customer, our left and right bending technology can help you gain high ROI for your continuous and stabilizable working in this industry.

Feel free to contact us if you have any questions or requirements, we will be in touch with you within 10 minutes and after getting your detailed request, we will analyze with our engineer together to find the best solution for you.